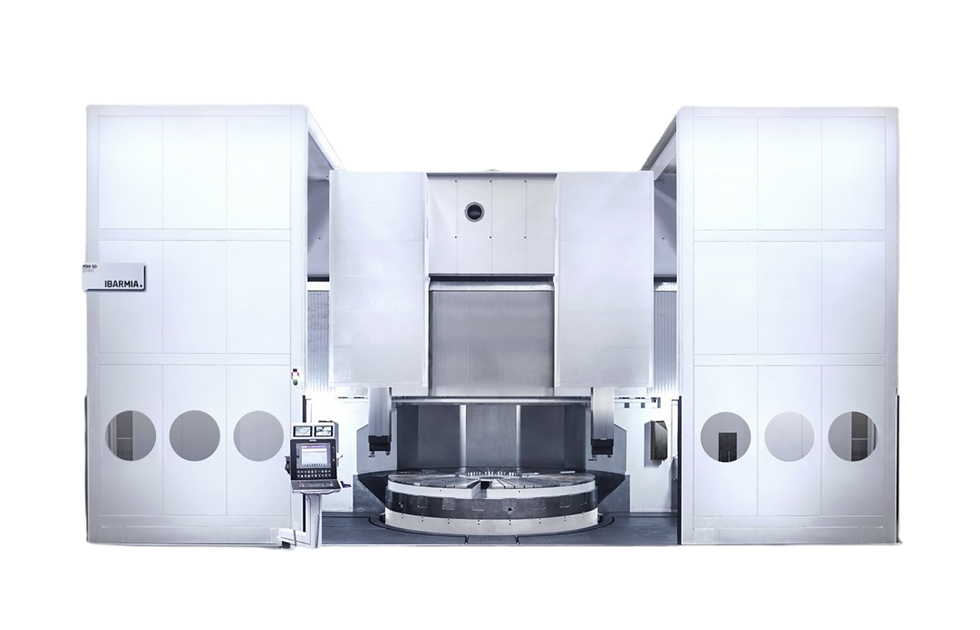

C-Series - Large Diameter Ring Production Centres

The IBARMIA C-Series is the ultimate solution for large diameter ring and flange production. Engineered for precision, power and reliability, these machines combine multiple operations such as turning, milling, drilling and boring into a single setup. Designed to handle workpieces up to 8.5 metres in diameter, the C-Series range offers exceptional rigidity and control, making it ideal for the manufacture of heavy, complex circular components in demanding sectors including energy, wind power, marine and heavy industry.

Why Choose DTS For IBARMIA C-Series Machinery?

DTS understands the challenges of machining very large, heavy components. As the UK distributor for IBARMIA, we combine expert knowledge with hands-on experience to help you get the best from your C-Series machines.

Partnering with DTS means you benefit from support designed specifically for large-diameter production, helping you maintain precision, efficiency, and reliability in every operation.

When you work with us, you gain:

-

Tailored machine selection to match your workpiece size, weight, and production requirements

-

Professional installation and commissioning designed for heavy, large-scale machinery

-

Hands-on training to ensure operators can safely and efficiently manage large rings, flanges, and casings

-

Ongoing technical support to maintain peak performance and reduce downtime

-

Specialist advice on workflows and fixturing for complex or oversized components

With DTS, you are not just purchasing a machine – you are gaining a partner who understands large-scale production and helps your operation run smoothly from setup to full productivity.

Advanced Solutions for Large-Diameter Machining

The IBARMIA C-Series provides exceptional precision, robustness, and versatility for the machining of large rings, flanges, bearings, and other substantial circular components. Capable of performing turning, drilling, and multi-process operations within a single setup, these machines deliver the reliability and performance required for demanding industrial applications.

Contact DTS today to discuss your requirements, arrange a demonstration, or explore how a C-Series machine can enhance your large-diameter production. Our team is committed to supporting your operation in achieving greater efficiency, reduced setup times, and consistently accurate results.

FREQUENTLY ASKED QUESTIONS

What is a drilling centre?

A drilling centre is a machining platform designed to perform precise drilling, boring, and milling on large or complex components. It typically uses a portal or moving-column structure to accommodate very large workpieces, offering extended travel and the ability to complete multiple operations in a single setup. Drilling centres are ideal for parts that require exact hole placement, alignment, and multi-axis machining without repeated handling.

What is a turning centre?

A turning centre is a machine that rotates the workpiece against a stationary cutting tool to remove material. C-Series turning centres are engineered for heavy-duty, large-diameter components such as rings, flanges, and bearings. They offer high rigidity, precision, and the capability to integrate additional operations such as milling or drilling, reducing handling and improving productivity.

What is the difference between turning centres and drilling centres?

Turning centres are designed to rotate the workpiece on a horizontal or vertical axis while a cutting tool removes material, making them ideal for large rings, flanges, and cylindrical components. Drilling centres, by contrast, are built to perform precise drilling, boring, and milling operations, often on very large or heavy workpieces. While turning centres excel in removing material from round parts, drilling centres are optimised for multi-axis drilling and complex machining of large components.

What are the advantages of turning centres?

Turning centres provide high precision, rigidity, and the ability to handle heavy or oversized parts. They reduce setup times by combining multiple operations, improve surface finish and dimensional accuracy, and allow for large-diameter components to be machined in a single setup. These machines are particularly suited to demanding sectors such as energy, offshore, marine, and heavy industry, where reliability and repeatability are critical.

Accreditations and memberships.