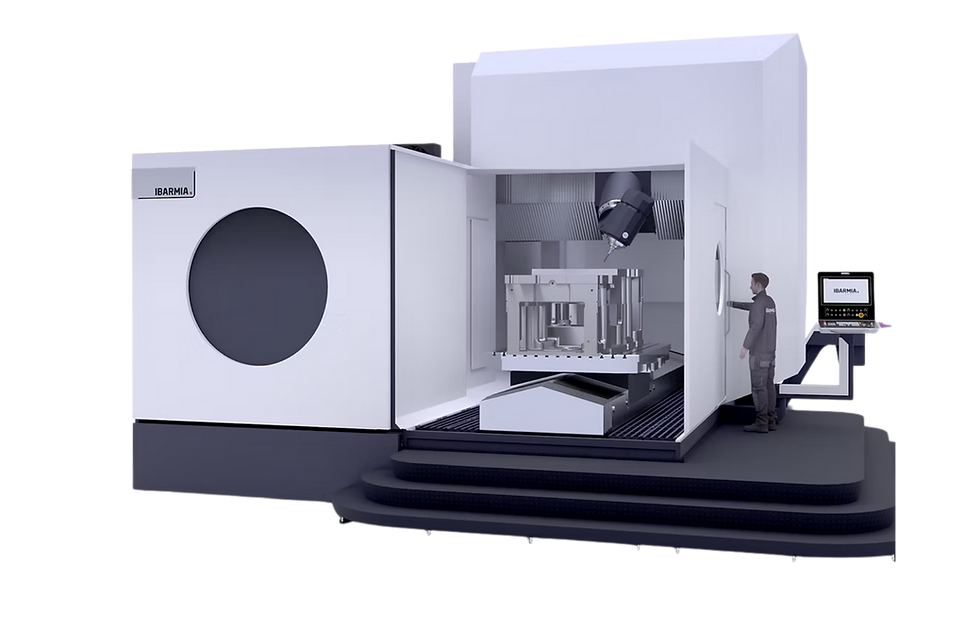

P-Series - Universal Portal Machining Centers

The IBARMIA P-Series represents the pinnacle of universal portal machining, combining strength, flexibility, and precision in one intelligent system. Designed for the efficient production of large, complex parts, these machines deliver superior rigidity, high spindle performance, and seamless automation. With adaptable configurations and advanced spindle head technology, the P-Series ensures optimal machining accuracy across every setup.

Why Choose DTS For IBARMIA P-Series Machinery?

At DTS, we understand that precision engineering is only part of the story. Efficiency, flexibility, and reliability are what truly drive success. The IBARMIA P-Series reflects these values, and our role is to help you realise its full potential within your production environment.

We take a consultative approach from day one, working with you to configure a solution that supports your workflow, automation goals, and long-term growth. From machine setup and tooling strategies to ongoing technical support, our team ensures your P-Series delivers exceptional performance year after year.

With DTS, you gain:

-

Industry insight shaped by decades of experience in advanced machining

-

A collaborative partnership focused on real-world results

-

End-to-end support covering installation, training, and optimisation

-

Rapid-response technical assistance from a dedicated UK team

-

Commitment to maximising uptime, precision, and productivity

Available sizes

The P-Series is available in three core sizes, each adaptable to meet specific production requirements:

-

P26 – Compact yet powerful, suited for medium-to-large parts

-

P30 – Versatile all-round model balancing capacity and footprint

-

P36 – Largest configuration for oversized components and maximum swing diameters

Spindle head models

Two high-performance spindle head options allow full customisation to application needs:

-

THC B-Axis Head: Tilting head with a −15° to +195° range, ideal for robust, high-torque applications requiring maximum flexibility.

-

THR A-Axis Head: Fork-type head with a −45° to +135° range, designed for high-speed, multi-directional 5-axis machining.

Take Your Machining to the Next Level with DTS UK

The IBARMIA T-Series 5-axis machining centres offer precision, flexibility, and heavy-duty performance for large, complex components. Whether you need multitasking capabilities with the Multiprocess models or high-speed, intricate milling with the Extreme series, DTS is here to help you find the perfect solution for your production needs.

Contact DTS today to discuss your requirements, arrange a demonstration, or explore how a T-Series machine can transform your manufacturing process. Let us help you maximise productivity, accuracy, and efficiency with the world-class performance of IBARMIA machinery.

FREQUENTLY ASKED QUESTIONS

What is the difference between P Multiprocess and P Extreme machining centres?

The P Multiprocess machines combine turning, milling, and drilling in a single setup, making them ideal for large components that require multitasking and reduced handling. P Extreme machines focus on high-precision 5-axis machining for complex geometries, delivering smooth motion and superior surface finish. Multiprocess emphasises versatility and efficiency, while Extreme prioritises accuracy and multi-face machining capabilities.

How do I choose the right P-Series model for my production needs?

Choosing the right P-Series machine depends on the size, weight, and complexity of the parts you produce, as well as your automation requirements. P26, P30, and P36 models offer different swing diameters and load capacities, while spindle head options provide further flexibility. Evaluating your production workflow with DTS ensures you select the machine that maximises efficiency, precision, and return on investment.

What are the different types of machining centres?

Machining centres are generally classified by their axis configuration and capabilities. Common types include 3-axis, 4-axis, and 5-axis machines, as well as multitasking or universal centres. Some are designed for horizontal turning, while others use vertical or portal configurations. Each type is optimised for specific operations such as milling, drilling, or multi-face machining.

What is a 5-axis machining centre?

A 5-axis machining centre can move a cutting tool or workpiece along five different axes simultaneously. This allows complex geometries to be machined in a single setup, improving accuracy and reducing handling. 5-axis centres are particularly useful for multi-face components, curved surfaces, and large parts where repositioning would otherwise be required.

What is the main advantage of the machining process?

The primary advantage of machining centres is the ability to perform multiple operations with high precision and repeatability. They reduce manual handling, minimise setup times, and ensure consistent part quality. For large or complex components, machining centres improve productivity while maintaining strict dimensional and surface finish standards.

Accreditations and memberships.